AISI 4130 90 Deg 3D Double Backed Elbow

Alloy Steel 4130 90 Deg 3D Double Backed Elbow

ANSI B16.9 4130 90 Deg 3D Double Backed Elbow

Kalikund Steel & Engineering Company (KSEC) is an established manufacturer, supplier, and distributor of AISI 4130 90 Degree 3d Double Backed Elbow in India. The AISI 4130 90 Degree 3d Double Backed Elbow is designed in 45 Degree 3D Doubled Backed Elbows and 90 Degree 3D Doubled Backed Elbows. The classification is based on the lengths of the elbows. Our AISI 4130 90 Degree 3d Double Backed Elbow come in a size range of 2” to 6” as well as other sizes requested by our customers. The features of AISI 4130 Degree 3d Double Backed Elbow are that it has smooth round uninterrupted bore facility that minimizes pressure drop and turbulence. It is also inherently stronger and supports high pressure operations.

AISI 4130 Degree 3d Double Backed Elbow is used in many application, as such, it is used in manufacturing of Choke & Kill manifolds including Control Panel, Cement Manifolds, and Mud Manifolds, manufacturing of Mud / Gas Separators, Oil & Gas and Oil Exploration industries, production of Pipe Line End Terminations and Manifold Equipment’s for it’s capable of surviving tremendous stress and pressure. Our AISI 4130 Degree 3d Double Backed Elbow is also functional in areas like Christmas Tree Equipments, Oil & Gas, Oil Exploration, High Pressure Jobs, Onshore offshore drilling, Rig projects, high pressure jobs and so on. At Kalikund Steel & Engineering Company (KSEC) we are keen on getting customer acclamation and hence keep quality first.

Dimensions : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

Size : 1", 2", 3", 4", 5", 6", 8", 3.5" OD, 4.5" OD, 5.5" OD and as per client design

Type : Seamless

Thickness :Schedule 80, XS, 120, 160, XXS, higher thickness as per client requirement.

Pressure :7.5K, 10K, 15K, 22.5K and more as per client drawing and requirement.

Delivery Condition : Annealed, Normalized, Stress Relieved, Quenched & Tempered.

Product Specification Level (PSL) : PSL 1, PSL 2, PSL 3.

Supplementary Requirement : NACE MR0175 / MR0103 ISO 3183 / NACE TM0284 YS - MIN 85,000, UTS - 1,10,000 WITHSTANDING 15,000 PRESSURE.

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| AISI 4130 | G41300 | 1.7218 | - | 25CrMo4 | JIS G4105 | BS 970 | - |

| Grade | Ni | C | Mo | Mn | Si | Fe | Cu | S | P | Cr | AISI 4130 | 0.50 max | 0.28-0.33 | 0.15-0.25 | 0.40-0.60 | 0.15-0.35 | 97.3-98.22 | - | 0.025 MAX | 0.035 MAX | 0.80-1.10 |

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 0.28 | 2580 | 460 MPa | 560 MPa | 20 % |

AISI 4130 90 Deg 3D Double Backed Elbow

Alloy Steel 4130 90 Deg 3D Double Backed Elbow

ANSI B16.9 4130 90 Deg 3D Double Backed Elbow

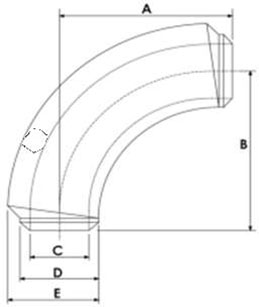

| NB | A | B | C | D | E | WEIGHT (KG) |

| 2” XXS | 7.00 | 7.00 | 1.50 | 2.37 | 3.50 | 11 |

| 3” XXS | 12.00 | 12.00 | 2.30 | 3.50 | 4.50 | 30 |

| 4” XXS | 14.00 | 14.00 | 3.15 | 4.50 | 5.50 | 47 |

| 5” XXS | 17.00 | 17.00 | 4.06 | 5.56 | 6.60 | 75 |

| 6” XXS | 21.00 | 21.00 | 4.90 | 6.63 | 8.25 | 135 |

| 5.5” OD x 3.0” ID | 17.00 | 17.00 | 3.06 | 5.50 | 6.60 | 80 |

| 6.75 OD x 5.00” ID | 21.00 | 21.00 | 5.00 | 6.75 | 8.25 | 135 |

Peru, Portugal, Poland, Spain, Saudi Arabia, KSA, Argentina, Turkey, denmark, Brazil, Jordan, Chile, Bahrain, Canada, Turkey, Ecuador, Chennai, Dammam, Spain, Russia, Africa, America, Kuwait, Indonesia, Nigeria, Ghana, Singapore, Himachal Pradesh, Jamnagar, Venezuela, USA, United Arab Emirates, Thailand, Malaysia, United States of America, Brazil, Angola, Mumbai, Sharjah, Hyderabad, Netherlands, Oman, UAE, Costa Rica, Bangalore, Abu Dhabi, Pune, , Gujarat, Norway, Texas, Visakhapatnam, Mexico, Colombia, Egypt, India, Houston, Qatar, Muscat, Coimbatore, Italy, Baroda, Bangalore, Riyadh, UK, Pimpri Chinchwad, United Kingdom, Dubai, etc