AISI 4130 Cross

Alloy Steel 4130 Cross

ANSI B16.9 4130 Cross

Kalikund Steel & Engineering Company (KSEC) is a renowned manufacturer, supplier, and distributor of AISI 4130 Cross. A cross in pipe fittings is also known as four-way fittings or cross branch lines. A cross has one inlet and three outlets forming the center of four connection points. The AISI 4130 Cross is resistant to high pressure and so are used in applications like High Pressure Jobs, Drilling Equipments, Onshore offshore drilling, Rig Projects, Deep Water riser system, Manifold Equipments, and so on. At Kalikund Steel & Engineering Company (KSEC) we ensure a high quality manufacturing of cross fittings making them rigid under all circumstances.

The AISI 4130 Cross ranges in sizes of 2” to 6” as well as other sizes as per customer requirements. Because of their tensile strength, corrosion resistance and dimensional accuracy, our AISI 4130 Cross is used in manufacturing of Choke & Kill manifolds including Control Panel, Mud Manifolds, and Cement Manifolds, manufacturing of Mud / Gas Separators, Oil & Gas and Oil Exploration industries, production of Pipe Line End Terminations and Manifold Equipment’s. There are various kind of crosses like the reducing cross, equal cross, threaded cross, etc. Our AISI 4130 Cross is manufactured using high quality raw materials for reliability and durability. Customer satisfaction is our prime goal and so we work continuously towards innovation and great service. The AISI 4130 Cross is applicable where high temperature and high pressure is required, for example, Oil Exploration, High Pressure Jobs, Drilling Equipments, Onshore offshore drilling, Rig Projects, and many more.

Dimensions : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

Size : 1", 2", 3", 4", 5", 6", 8", 3.5" OD, 4.5" OD, 5.5" OD and as per client design

Type : Seamless

Thickness :Schedule 80, XS, 120, 160, XXS, higher thickness as per client requirement.

Form : Equal Cross, Unequal Cross, Reducing Cross.

Pressure :7.5K, 10K, 15K, 22.5K and more as per client drawing and requirement.

Delivery Condition : Annealed, Normalized, Stress Relieved, Quenched & Tempered.

Product Specification Level (PSL) : PSL 1, PSL 2, PSL 3.

Supplementary Requirement : NACE MR0175 / MR0103 ISO 3183 / NACE TM0284 YS - MIN 85,000, UTS - 1,10,000 WITHSTANDING 15,000 PRESSURE.

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| AISI 4130 | G41300 | 1.7218 | - | 25CrMo4 | JIS G4105 | BS 970 | - |

| Grade | Ni | C | Mo | Mn | Si | Fe | Cu | S | P | Cr | AISI 4130 | 0.50 max | 0.28-0.33 | 0.15-0.25 | 0.40-0.60 | 0.15-0.35 | 97.3-98.22 | - | 0.025 MAX | 0.035 MAX | 0.80-1.10 |

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 7.85g/cm3 | 1432 C | 460 MPa | 560 MPa | 21.50 % |

AISI 4130 Cross

Alloy Steel 4130 Cross

ANSI B16.9 4130 Cross

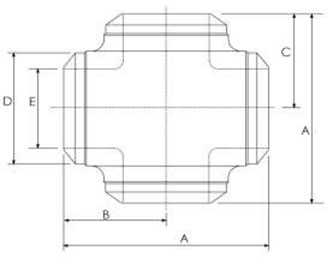

| NB | A | B | C | D | E | WEIGHT (KG) |

| 2” XXS | 5.04 | 2.52 | 2.52 | 1.50 | 2.37 | 4 |

| 3” XXS | 6.78 | 3.39 | 3.39 | 2.30 | 3.50 | 9 |

| 4” XXS | 8.24 | 4.12 | 4.12 | 3.15 | 4.50 | 18 |

| 5” XXS | 9.76 | 4.88 | 4.88 | 4.06 | 5.56 | 26 |

| 6” XXS | 11.26 | 5.63 | 5.63 | 4.90 | 6.63 | 40 |

| 5.5” OD x 3” ID | 9.76 | 4.88 | 4.88 | 3.00 | 5.50 | 30 |

| 6.75” OD x 5” ID | 11.26 | 5.63 | 5.63 | 4.90 | 6.63 | 42 |

Baroda, Portugal, Poland, denmark, USA, Brazil, Spain, Sharjah, Russia, India, Dubai, Houston, Brazil, Gujarat, Hyderabad, Colombia, Argentina, Texas, Singapore, Angola, Pune, Ghana, Egypt, United Arab Emirates, America, Kuwait, Qatar, Netherlands, Oman, Thailand, Himachal Pradesh, Italy, Costa Rica, Spain, Visakhapatnam, Saudi Arabia, Canada, Bangalore, Coimbatore, Turkey, Abu Dhabi, Venezuela, Mexico, Bangalore, Malaysia, Jordan, Bahrain, Africa, United States of America, KSA, Chile, UAE, Muscat, United Kingdom, UK, Riyadh, Nigeria, Indonesia, Norway, Ecuador, Chennai, Jamnagar, Mumbai, Dammam, Peru, Turkey, Pimpri Chinchwad, etc