AISI 4130 45 Deg Long Radius Elbow

Alloy Steel 4130 45 Deg Long Radius Elbow

ANSI B16.9 4130 45 Deg Long Radius Elbow

Kalikund Steel & Engineering Company (KSEC) is a prominent manufacturer, supplier, and distributor of AISI 4130 45 Deg Long Radius Elbow. An elbow is manufactured to allow a change of direction and is installed between two lengths of pipe. Elbows allow the change of direction in 90 Degree or 45 Degree. A 45 Degree Long Radius Elbow is also known as a “45 bend” or “45 ell”, and is commonly used in food, chemical, water-supply facilities, pipeline networks, agriculture and garden production, and solar-energy facility piping. Kalikund Steel & Engineering Company is a renowned company to manufacture the best AISI 4130 45 Deg Long Radius Elbow in India. As the name suggests, AISI 4130 45 Deg Long Radius Elbow is a pipe fitting device which is bent in a 45 Degree angle to change the direction of the flow of the fluid/gas in 45 Deg in the pipe.

The AISI 4130 45 Deg Long Radius Elbow is constructed for rigid applications like cryogenic and high temperature resistance and hence it is used in manufacturing of Choke & Kill manifolds including Control Panel, Cement Manifolds, and Mud Manifolds, manufacturing of Mud / Gas Separators, and production of Pipe Line End Terminations and Manifold, Oil & Gas and Oil Exploration industries. Our AISI 4130 45 Deg Long Radius Elbow is also applicable in areas like Well Test Equipments, Pipe Line end Manifolds, Pipe Line end Terminations, Subsea Wellhead and many more such areas. We, at Kalikund Steel & Engineering Company (KSEC) work towards continuous customer satisfaction and have hence received customer acclamation.

Dimensions : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

Size : 1", 2", 3", 4", 5", 6", 8", 3.5" OD, 4.5" OD, 5.5" OD and as per client design

Type : Seamless

Thickness :Schedule 80, XS, 120, 160, XXS, higher thickness as per client requirement.

Pressure :7.5K, 10K, 15K, 22.5K and more as per client drawing and requirement.

Delivery Condition : Annealed, Normalized, Stress Relieved, Quenched & Tempered.

Product Specification Level (PSL) : PSL 1, PSL 2, PSL 3.

Supplementary Requirement : NACE MR0175 / MR0103 ISO 3183 / NACE TM0284 YS - MIN 85,000, UTS - 1,10,000 WITHSTANDING 15,000 PRESSURE.

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| AISI 4130 | G41300 | 1.7218 | - | 25CrMo4 | JIS G4105 | BS 970 | - |

| Grade | Ni | C | Mo | Mn | Si | Fe | Cu | S | P | Cr | AISI 4130 | 0.50 max | 0.28-0.33 | 0.15-0.25 | 0.40-0.60 | 0.15-0.35 | 97.3-98.22 | - | 0.025 MAX | 0.035 MAX | 0.80-1.10 |

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 0.28 | 2580 | 460 MPa | 560 MPa | 20 % |

AISI 4130 45 Deg Long Radius Elbow

Alloy Steel 4130 45 Deg Long Radius Elbow

ANSI B16.9 4130 45 Deg Long Radius Elbow

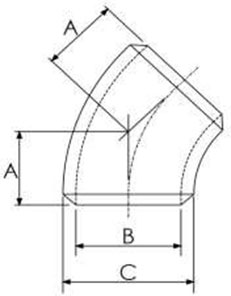

| NB | A | B | C | WEIGHT (KG) |

| 2” XXS | 1.38 | 1.50 | 2.37 | 1 |

| 3” XXS | 2.00 | 2.30 | 3.50 | 3 |

| 4” XXS | 2.50 | 3.15 | 4.50 | 5 |

| 5” XXS | 3.10 | 4.06 | 5.56 | 9 |

| 6” XXS | 3.75 | 4.90 | 6.63 | 15 |

| 5.5” OD x 3” ID | 3.10 | 3.00 | 5.50 | 12 |

| 6.75” OD x 5” ID | 3.75 | 5.00 | 6.75 | 16 |

UK, Dammam, Pune, Mexico, Argentina, Canada, Russia, United Arab Emirates, Chennai, Mumbai, Spain, Ghana, Saudi Arabia, Egypt, KSA, Norway, Poland, Singapore, Houston, Italy, Qatar, Visakhapatnam, Africa, Pimpri Chinchwad, Texas, denmark, Peru, Turkey, United Kingdom, Ecuador, Bangalore, America, Chile, Thailand, Indonesia, Dubai, Spain, Muscat, Colombia, Turkey, Gujarat, Costa Rica, Jamnagar, Malaysia, UAE, USA, Abu Dhabi, Brazil, Netherlands, Jordan, Coimbatore, Nigeria, Hyderabad, Angola, Riyadh, Bahrain, Sharjah, Portugal, Kuwait, Venezuela, Baroda, Oman, Brazil, Bangalore, India, Himachal Pradesh, United States of America, etc